FOAM DUNNAGE

SES Packaging Systems offers both expendable and returnable foam dunnage to fit your application. Our focus is providing custom foam protection packaging for the automotive industry, but we also provide packaging to non-automotive industries such as high-tech, pharmaceutical, construction and others. Using various materials and our manufacturing capabilities, we can provide a one-time use foam dunnage solution (Expendable) or foam dunnage that will last multiple years (Returnable). Manufacturers rely on our design team for reliable, effective protective packaging for a wide range of parts. We provide exceptional care and customization to your protective equipment projects. Ensuring that you have the equipment required to support your customers and business.

FEATURES

-

✺

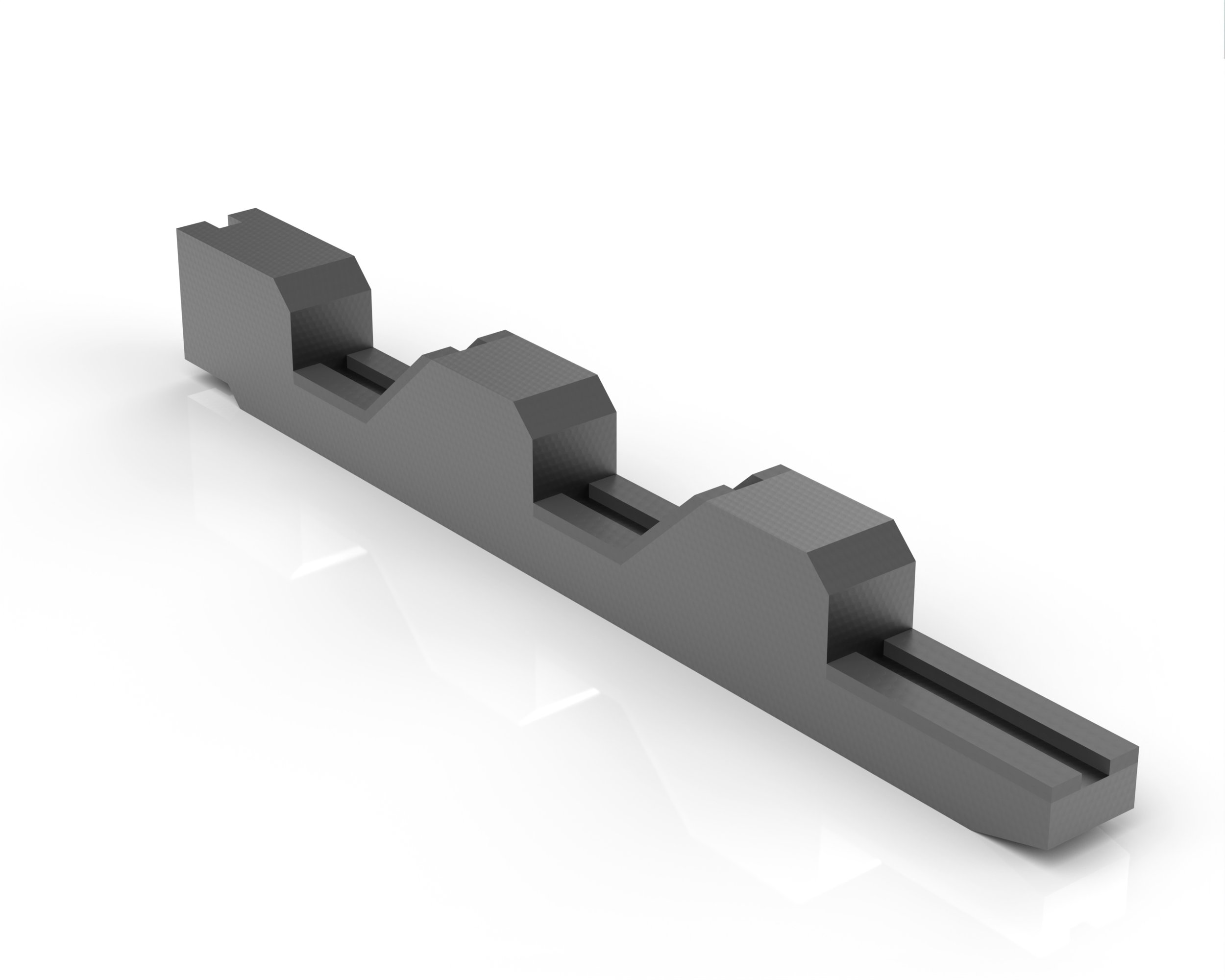

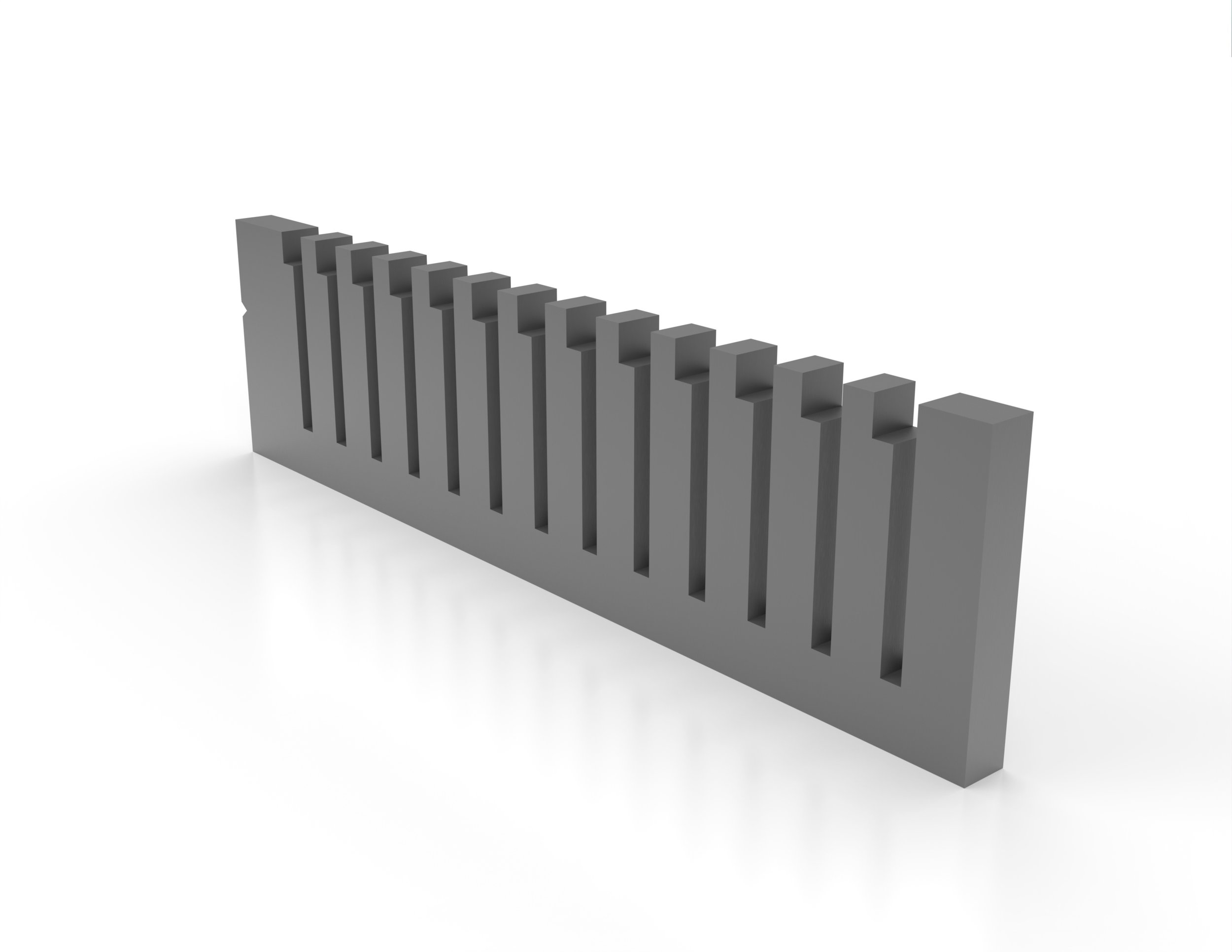

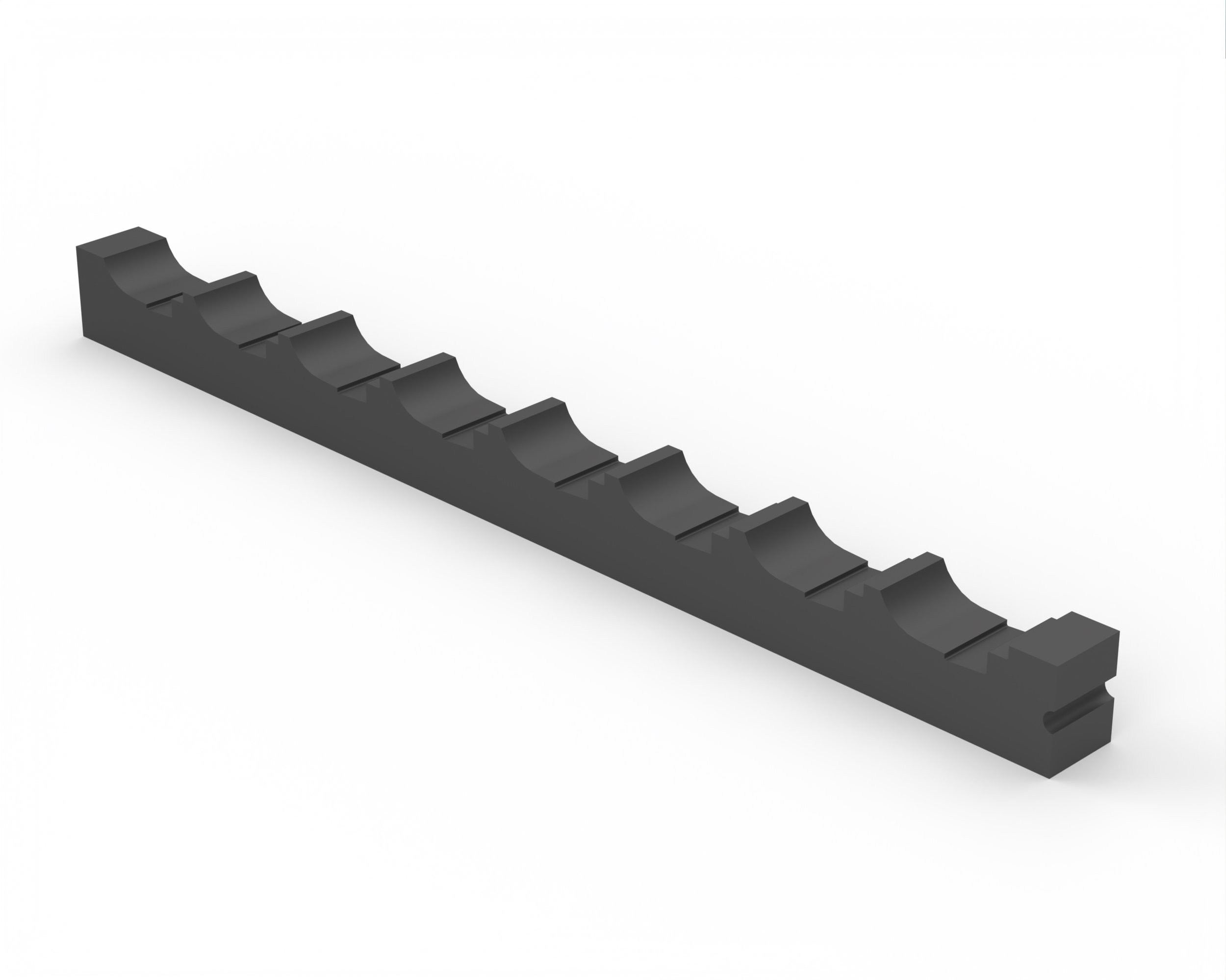

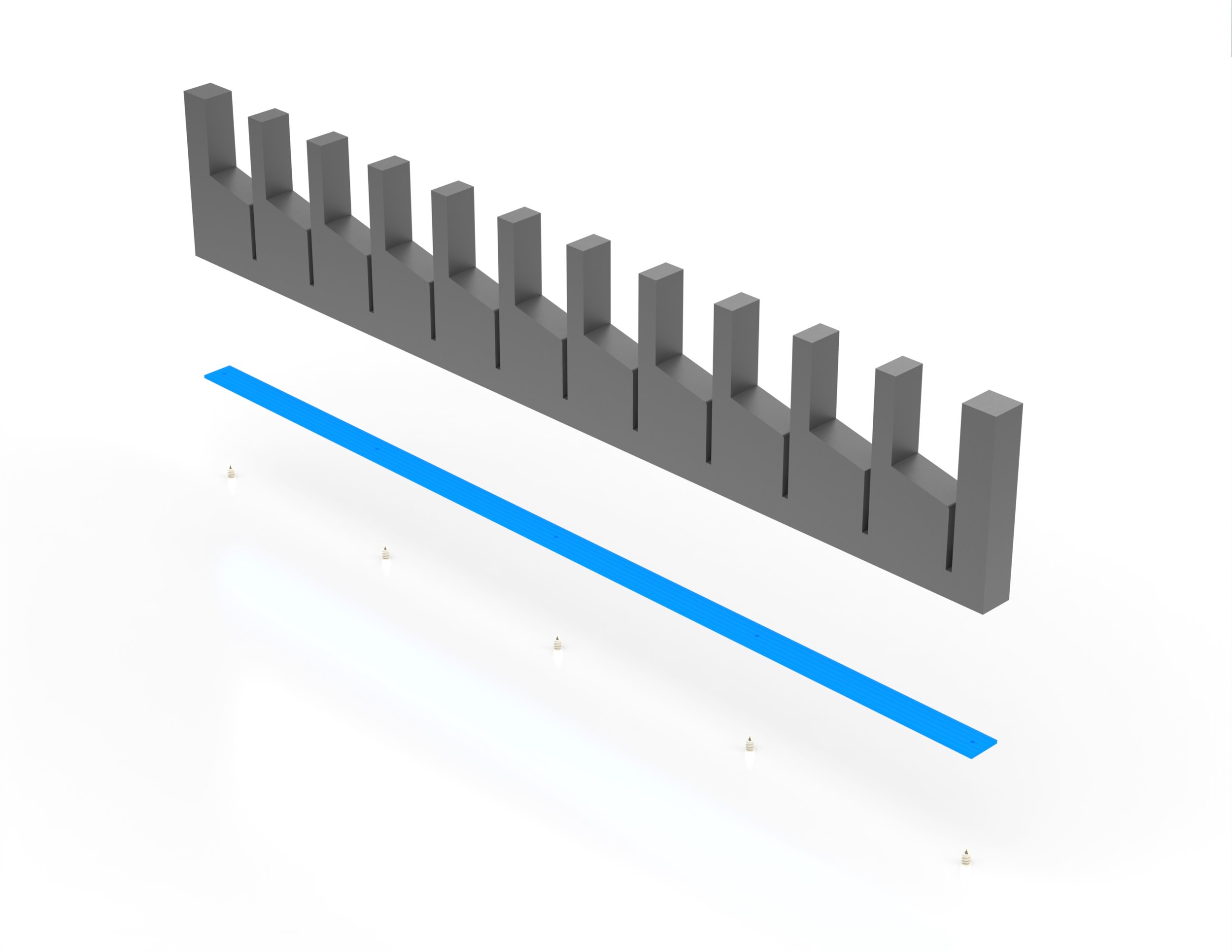

Foam dunnage is the foam material used to protect goods during shipping.

-

✺

Soft dunnage materials or low density. Soft dunnage options are used when transporting lightweight and small/medium packages, usually expendable.

-

✺

Harder dunnage materials or high density. This dunnage is used for heavy parts and longevity, usually returnable.

FIND OUT MORE

Interested in learning more? Fill out the form below and one of our representatives will contact you.

RESOURCES

-

What type of material do we use? 6 major materials.

XLPE Foam - Cross-linked polyethylene foam (also known as XLPE) is a closed-cell foam characterized by a micro-cellular appearance and resistance to water. XLPE materials are used in applications that require protection of class “A” surfaces. XLPE foam is used extensively in packaging, moulded and die cut gaskets and seals. For die cut foam inserts and packaging, contact us today.

PE Foam - Polyethylene foam is strong and resilient closed‐cell foam, ideally suited to absorbing shock in protective and cushion packaging applications.

PU Foam - a flexible material, polyurethane foam is produced from combining polyol, isocyanate, and water. Polyurethane custom foam padding is highly durable and is used as cushioning in a wide array of products, such as packaging, furniture, car seats, and mattresses.

Bubble Guard Board - Bubble GUARD is a multi-layer alveolar board made from 100% polypropylene with a unique circular honeycomb structure core at the centre and two flat surfaces on either side with great versatility and high performances. It is 100% eco-friendly & recyclable. Also available is the DOUBLE LAYER BUBBLEGUARD board with the highest weight range up to 6000 GSM.

Fluted Polypropylene Coroplast - rigid material made of polypropylene plastic. Sheets of Coroplast have a fluted core and are smooth on both faces and are available with different material laminations on one or both sides.

Kraft Paper - Kraft paper is produced through the chemical conversion of wood pulp, resulting in a strong and durable paper product.

-

No. Our orders range from $25.00 to $250 000.00 +

-

The latest up to date equipment required for fabrication of packaging products.

-

Depending on the packaging that is manufactured. Generally, all expendable packing is manufactured and shipped in 24 to 48 hours. Returnable packing, depending on the order size, material availability and complexity can range from a couple of days to 3 or 4 weeks.