PLASTIC CORRUGATED PACKAGING

SES Packaging Systems specializes in plastic corrugated manufacturing providing packaging solutions that are simple yet cost-effective. With a combination of broad range of plastic corrugated material and excellent material supplier base, SES insures short lead-times and access to many materials. This access to a variety of materials allows us to address any number of variants that affect the usability, quality, and functionality of the overall packaging solution.

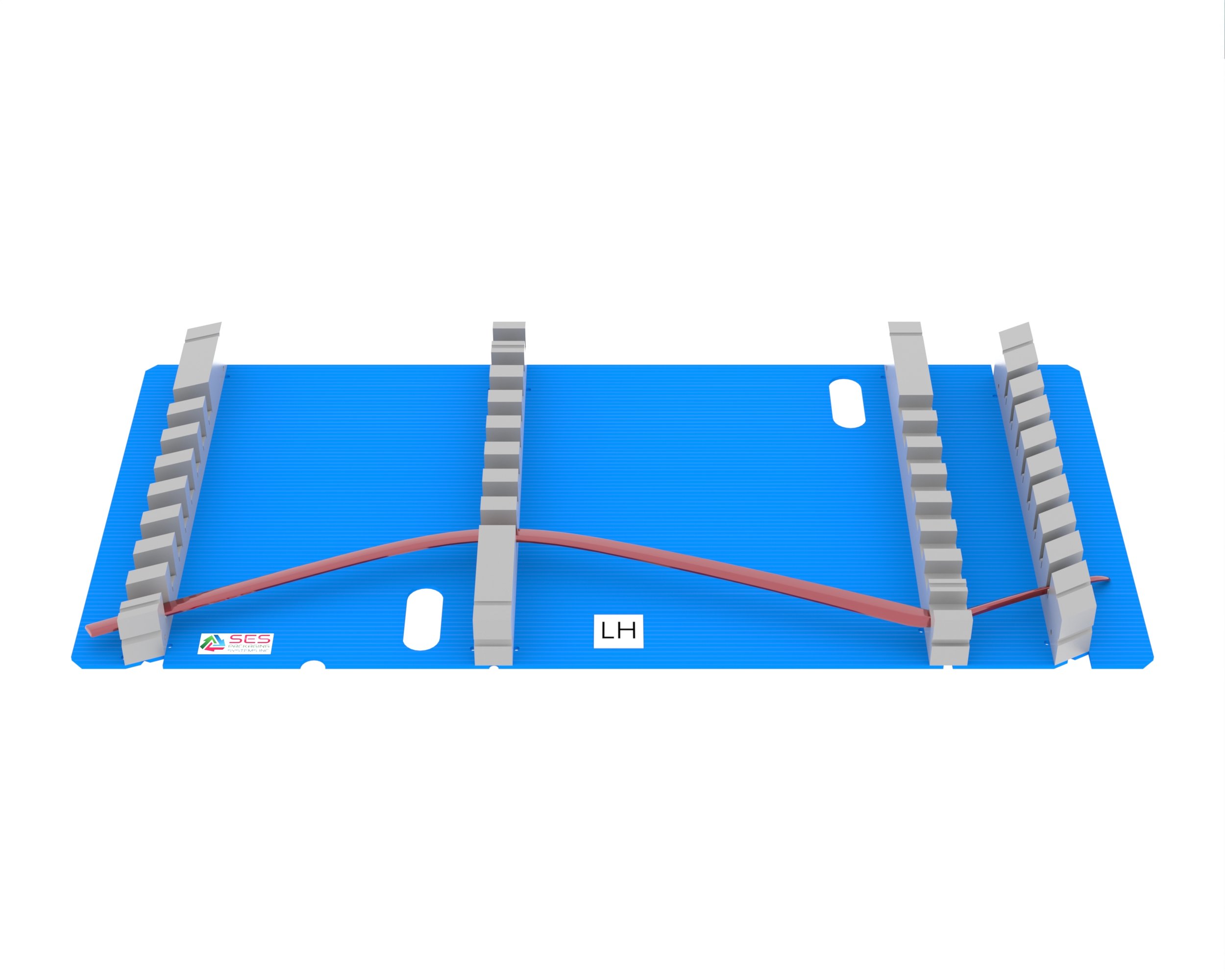

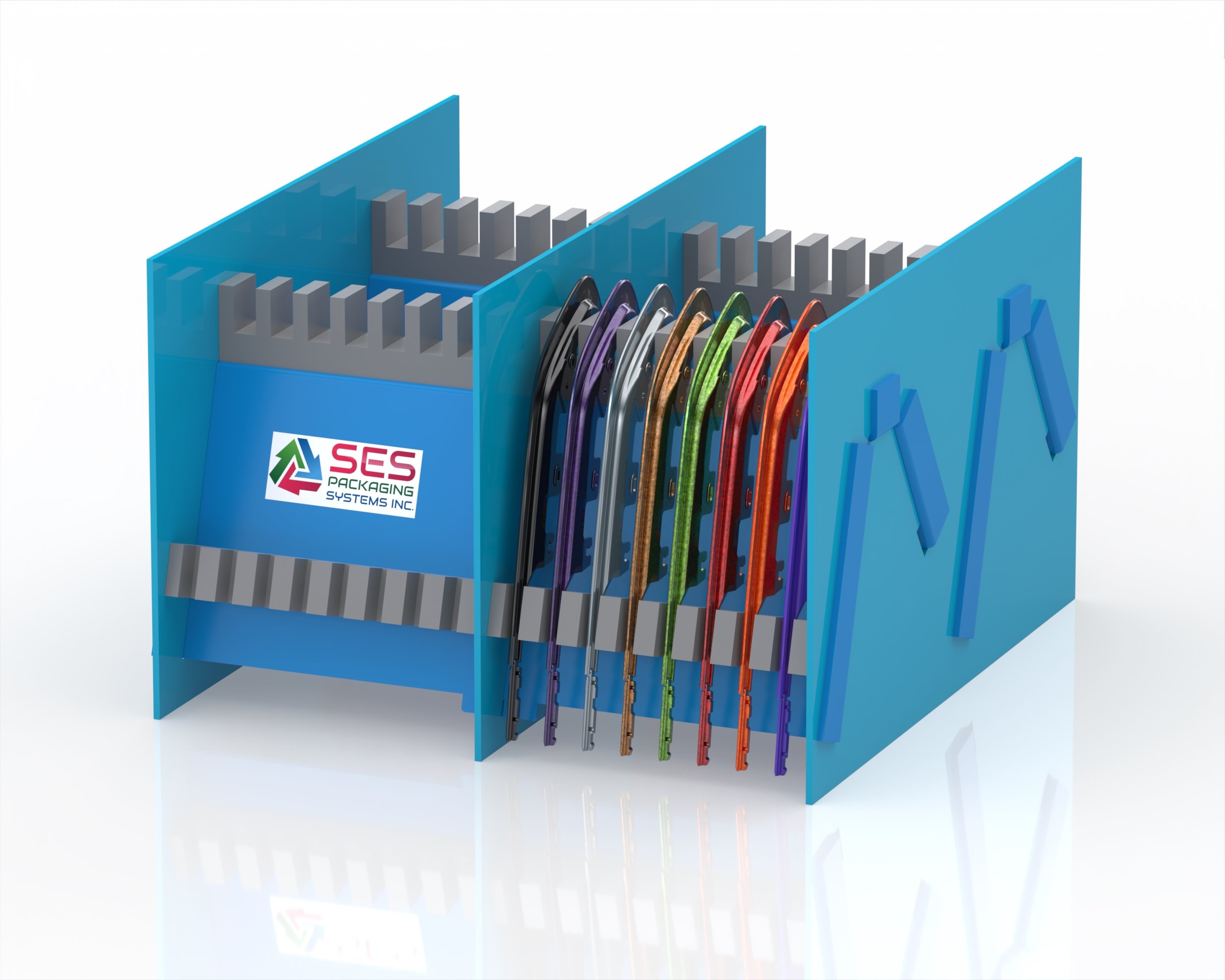

Laminated Plastic Corrugation

Like our plastic corrugated partitions, SES Packaging Systems also specializes in laminated partition manufacturing providing packaging solutions that are designed to meet performance criteria such as class A surface protection, durability, etc. With a combination of a broad range of laminations such as XLPE, Brush nylon, Spuntex and others, SES insures material availability for your application. This access to a variety of materials allows us to address any number of variants that affect the usability, quality, and functionality of the overall packaging solution.

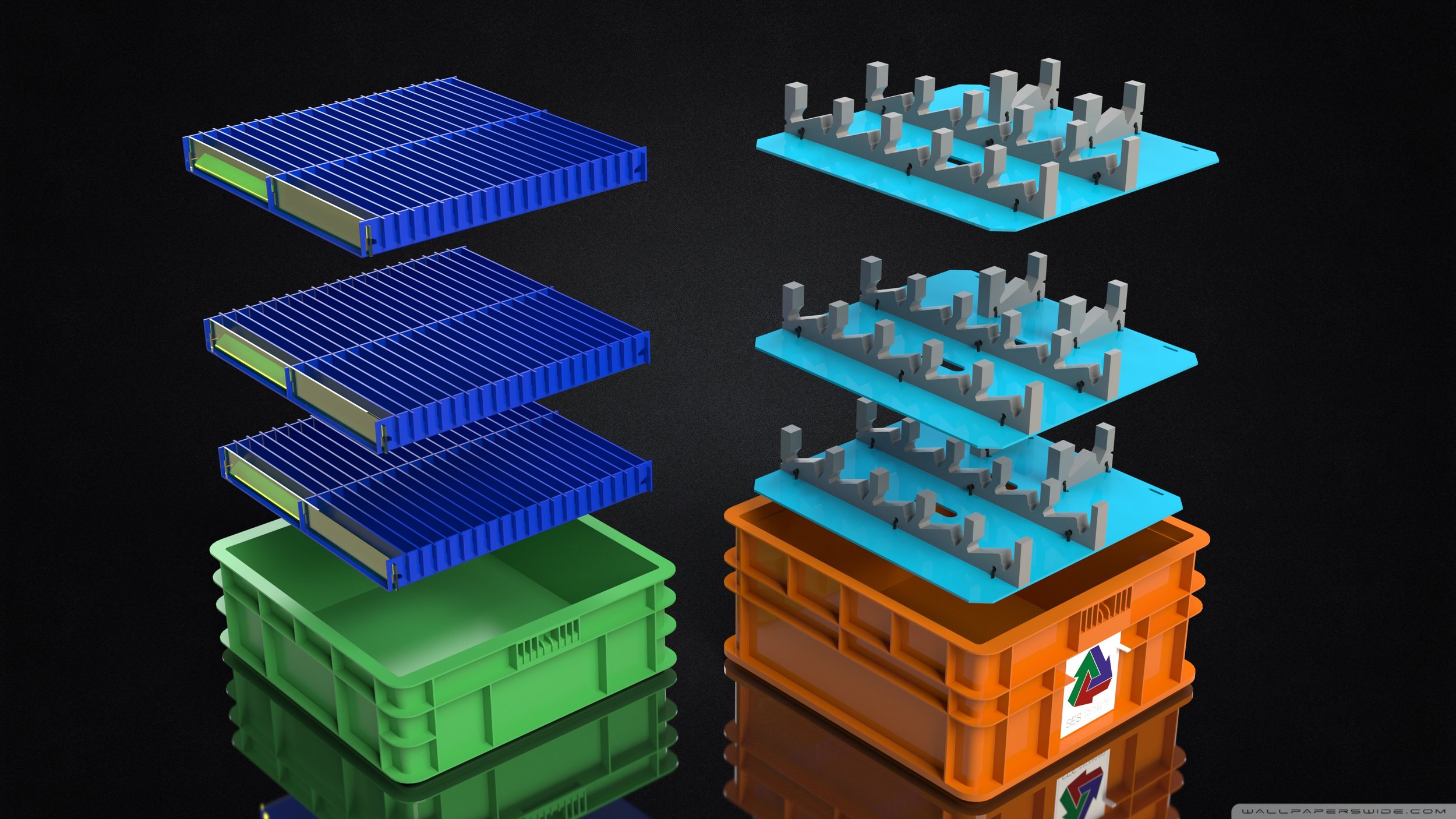

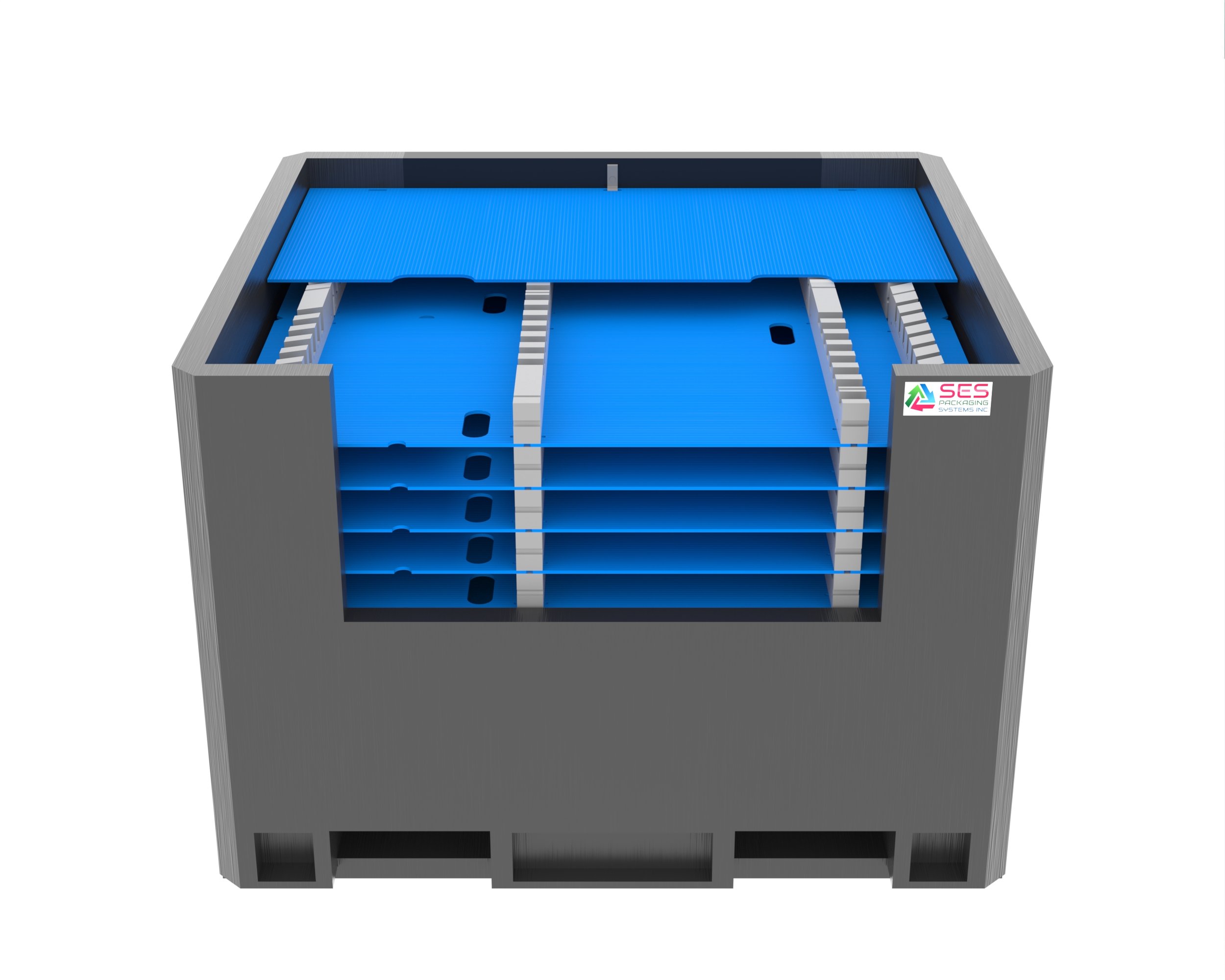

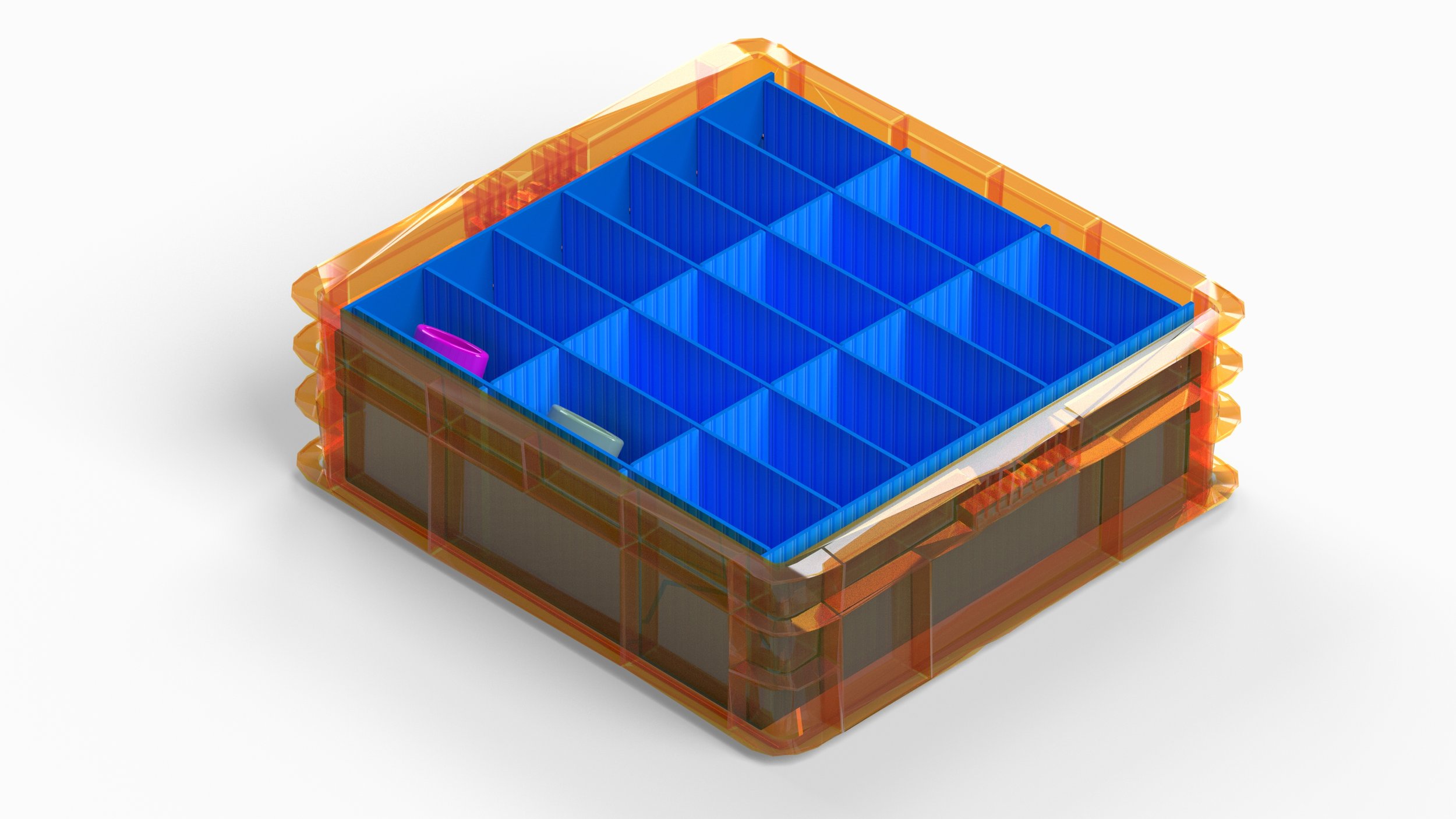

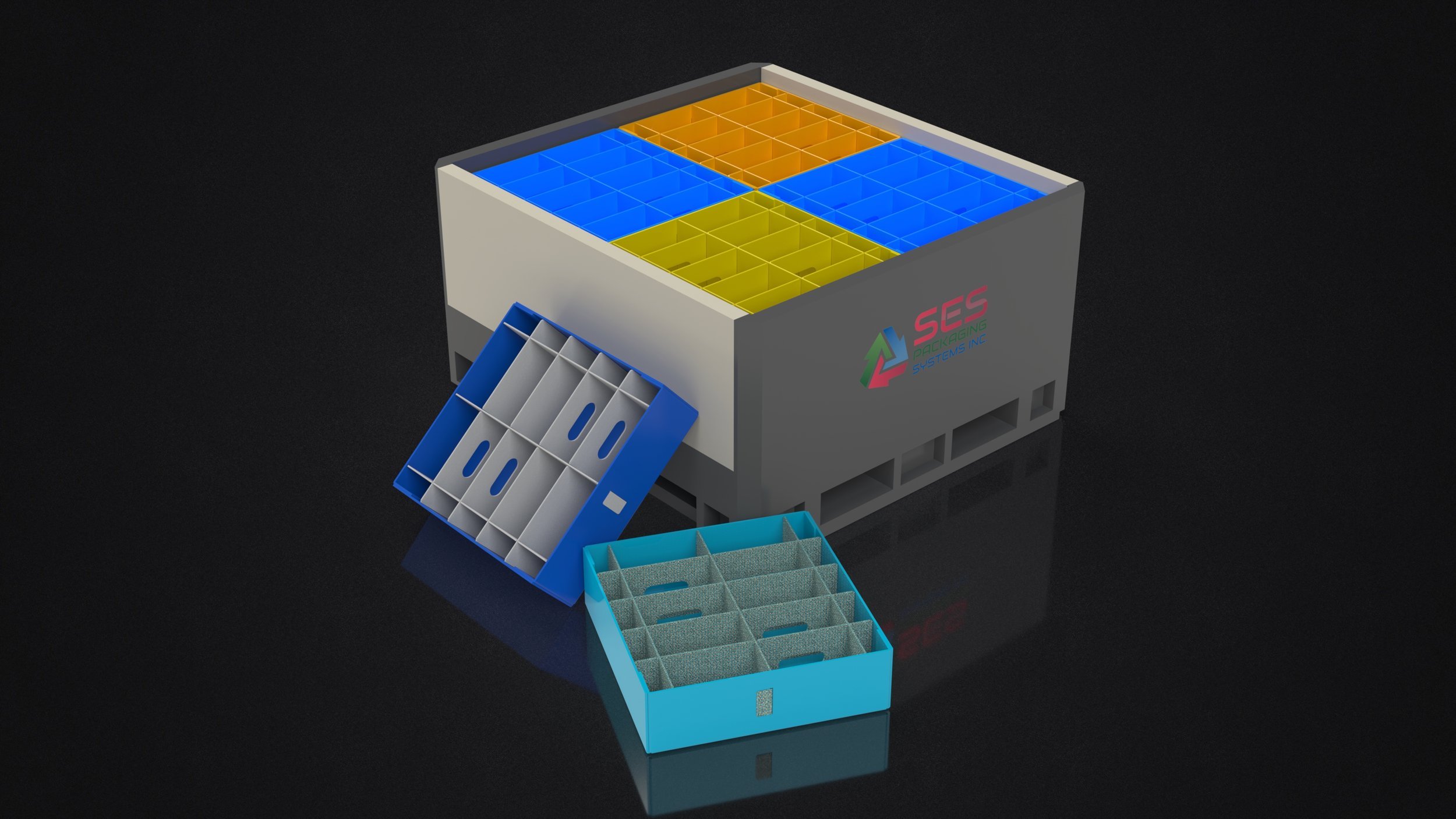

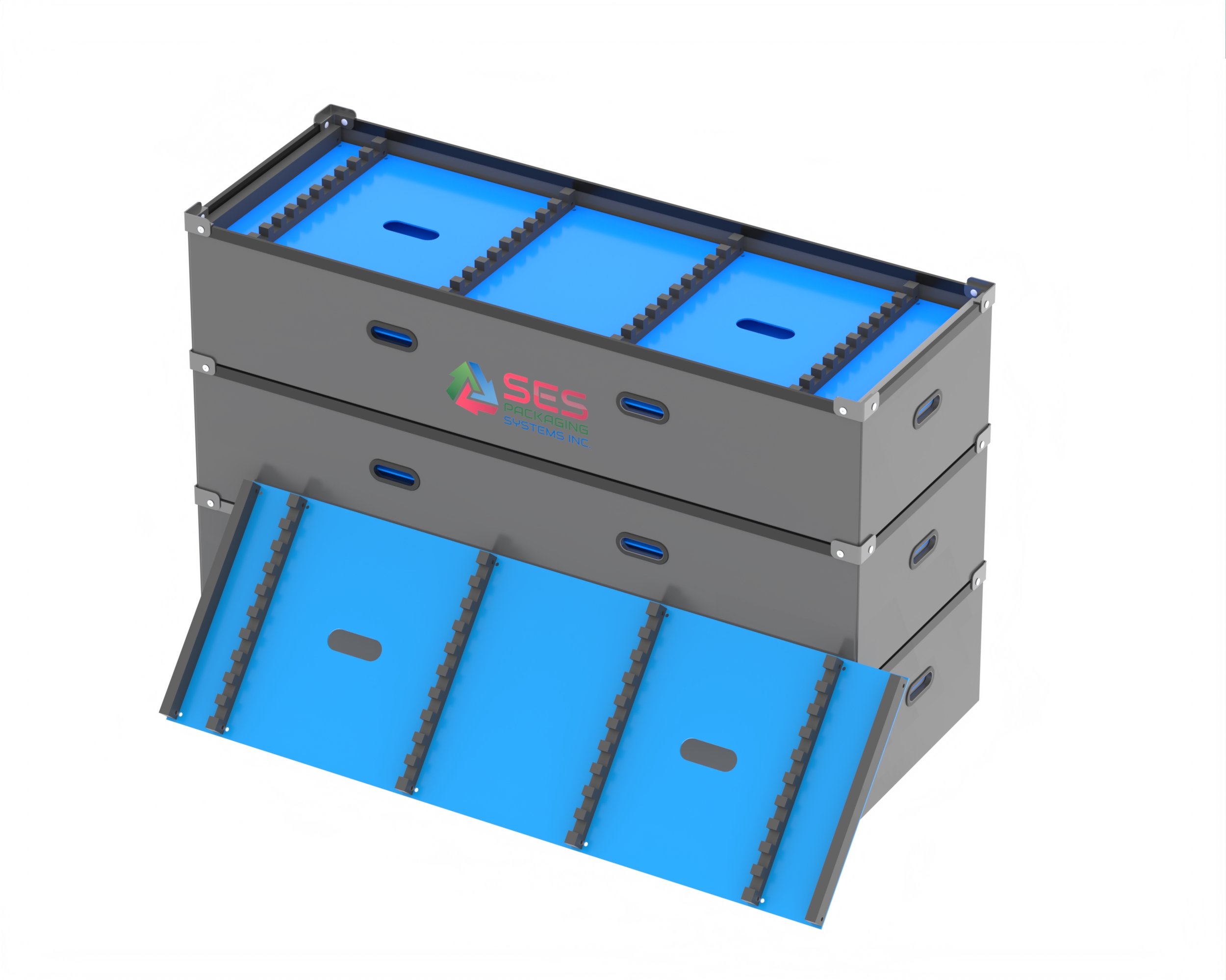

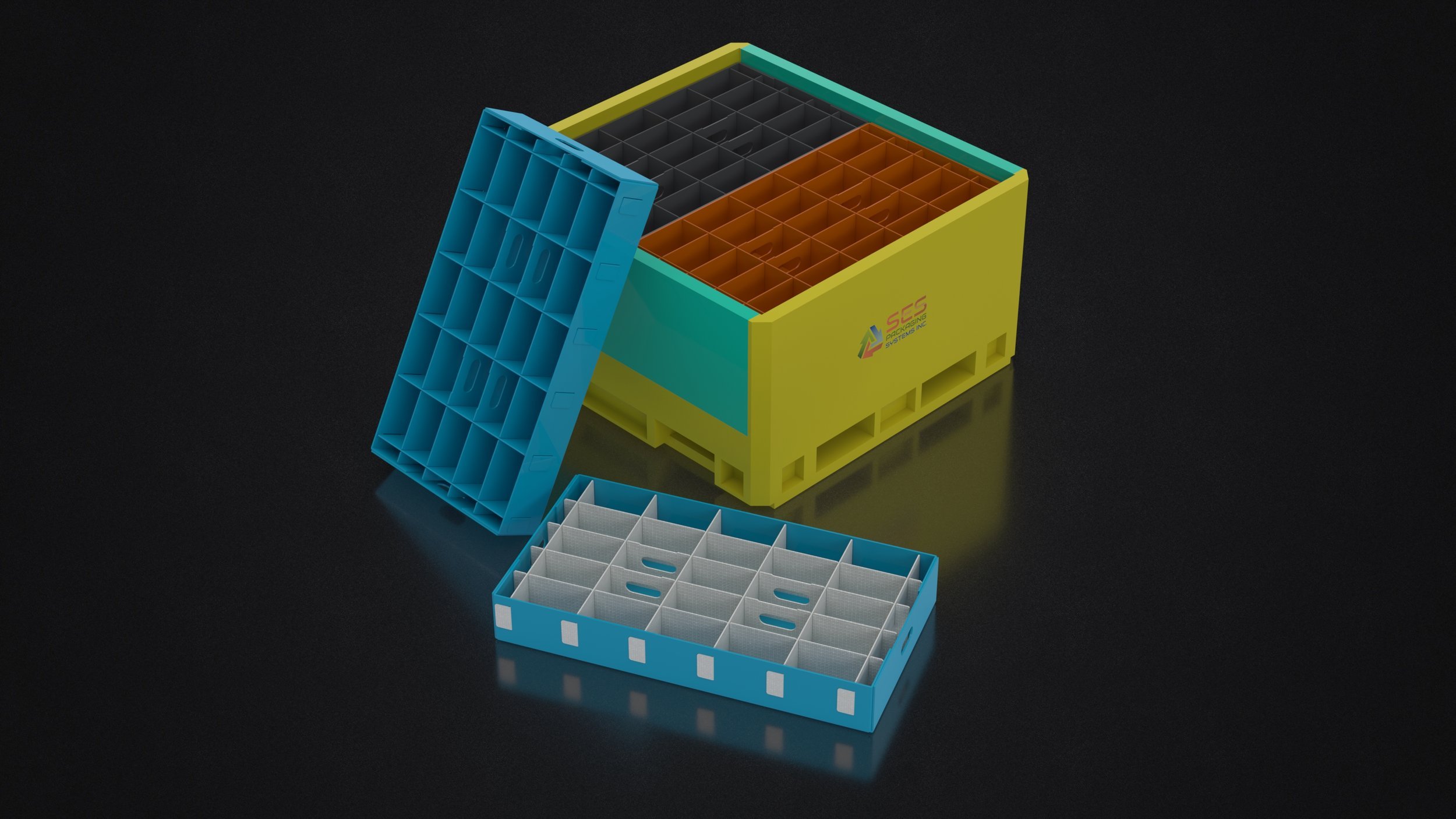

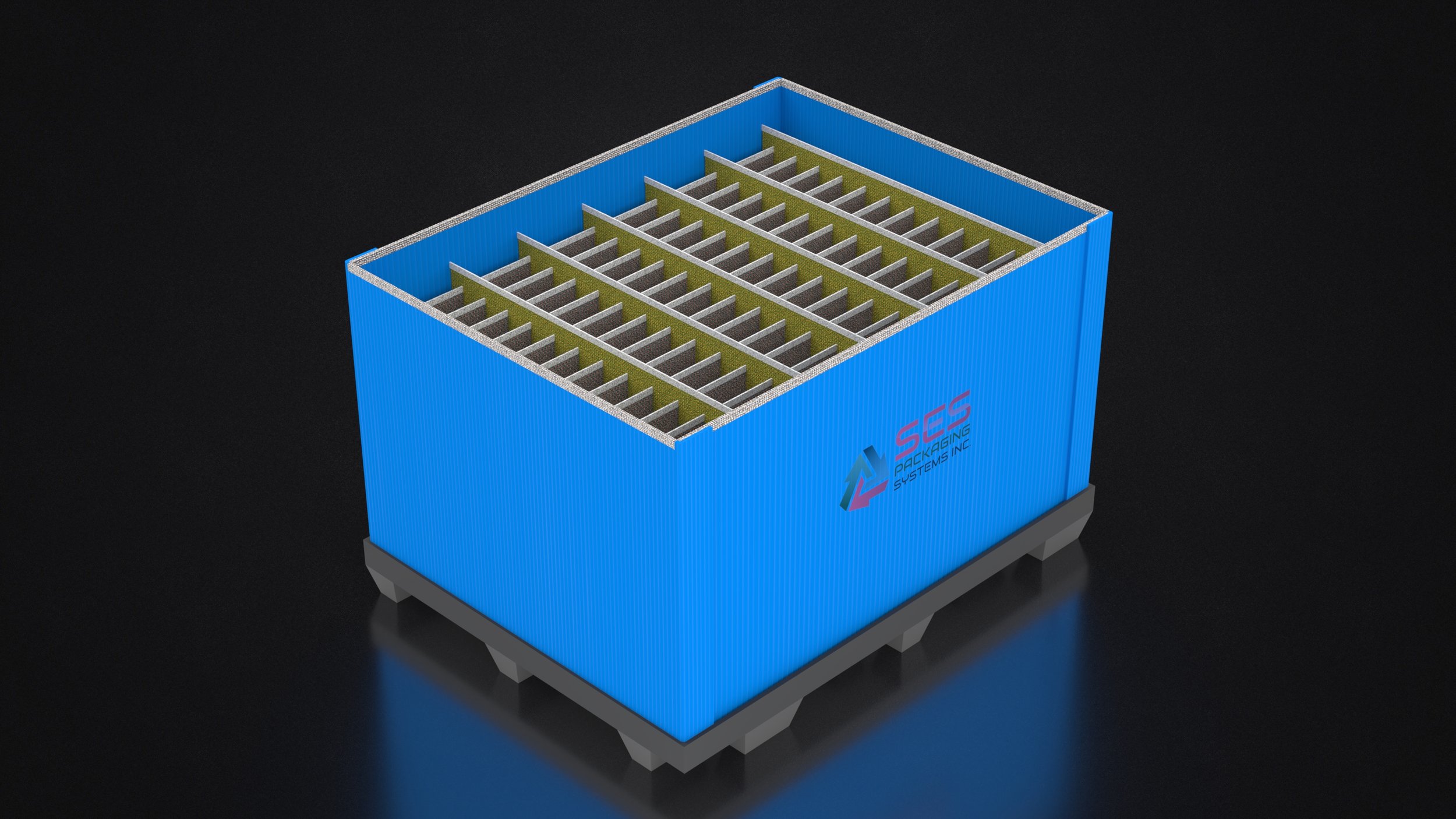

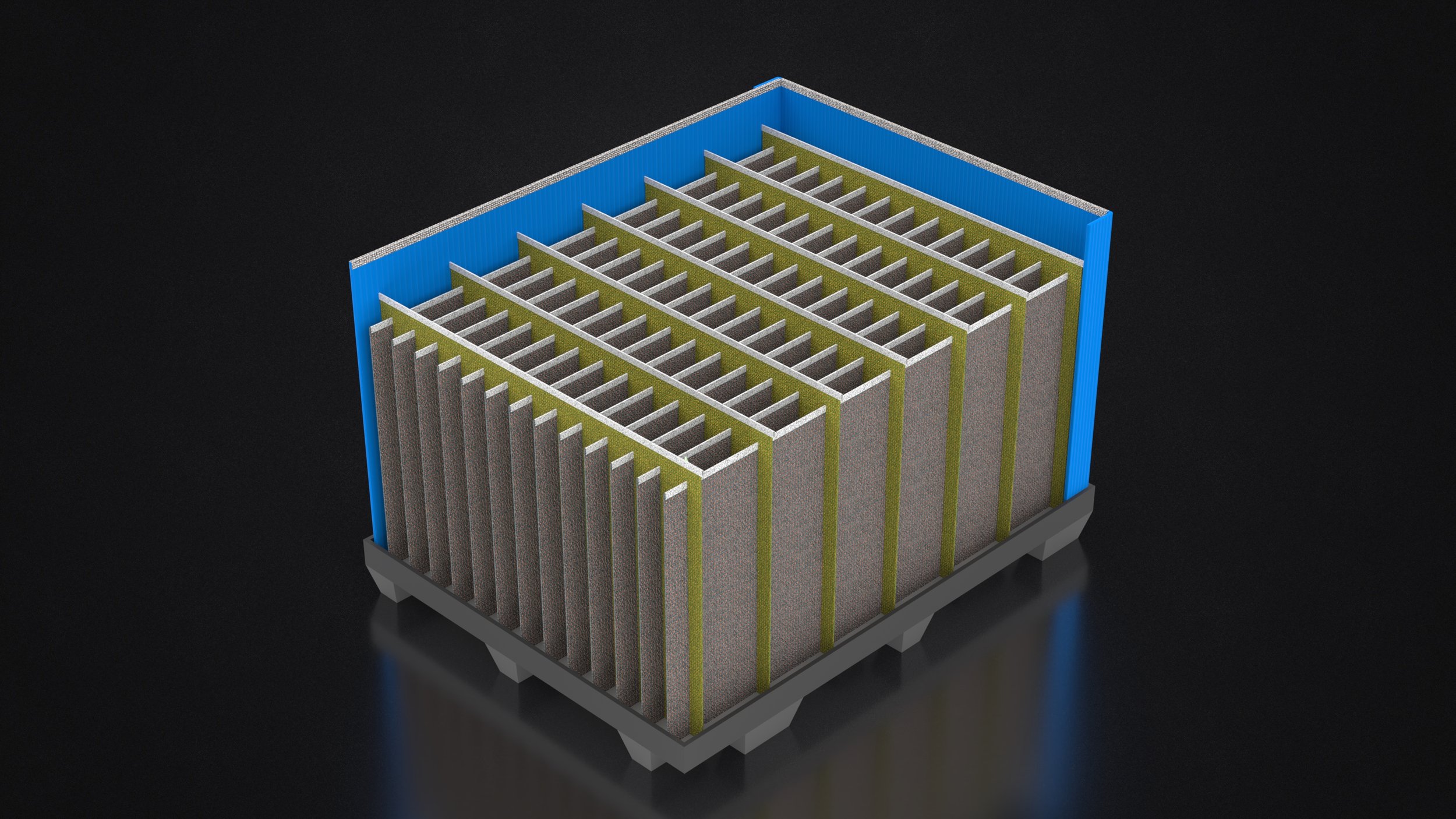

Plastic Corrugation Partitions

SES Packaging Systems can produce fully assembled corrugated partitions to match almost any application.

Our packaging designers and sales associates will work with you and will match right packaging solution for your specific requirements.

Corrugated partitions can be used in totes, crates, or boxes and customized to protect your raw parts or finished product.

FEATURES

-

✺

Can be removed in the manufacturing work cell or tethered to a tote/container

-

✺

Designed with variety of materials and laminations

-

✺

Designed to eliminate part damage and reduce assembly errors

FIND OUT MORE

Interested in learning more? Fill out the form below and one of our representatives will contact you.

RESOURCES

-

What type of material do we use? 6 major materials.

XLPE Foam - Cross-linked polyethylene foam (also known as XLPE) is a closed-cell foam characterized by a micro-cellular appearance and resistance to water. XLPE materials are used in applications that require protection of class “A” surfaces. XLPE foam is used extensively in packaging, moulded and die cut gaskets and seals. For die cut foam inserts and packaging, contact us today.

PE Foam - Polyethylene foam is strong and resilient closed‐cell foam, ideally suited to absorbing shock in protective and cushion packaging applications.

PU Foam - a flexible material, polyurethane foam is produced from combining polyol, isocyanate, and water. Polyurethane custom foam padding is highly durable and is used as cushioning in a wide array of products, such as packaging, furniture, car seats, and mattresses.

Bubble Guard Board - Bubble GUARD is a multi-layer alveolar board made from 100% polypropylene with a unique circular honeycomb structure core at the centre and two flat surfaces on either side with great versatility and high performances. It is 100% eco-friendly & recyclable. Also available is the DOUBLE LAYER BUBBLEGUARD board with the highest weight range up to 6000 GSM.

Fluted Polypropylene Coroplast - rigid material made of polypropylene plastic. Sheets of Coroplast have a fluted core and are smooth on both faces and are available with different material laminations on one or both sides.

Kraft Paper - Kraft paper is produced through the chemical conversion of wood pulp, resulting in a strong and durable paper product.

-

No. Our orders range from $25.00 to $250 000.00 +

-

The latest up to date equipment required for fabrication of packaging products.

-

Depending on the packaging that is manufactured. Generally, all expendable packing is manufactured and shipped in 24 to 48 hours. Returnable packing, depending on the order size, material availability and complexity can range from a couple of days to 3 or 4 weeks.